Furnace Glossary

This website is for informational purposes only.

Advanpro Ltd. is not liable for property damage, personal injury, or death caused directly or indirectly by actions taken as a result of the information provided here.

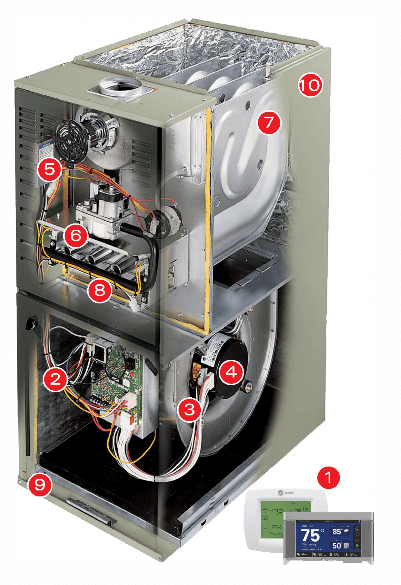

A typical gas furnace

1. Thermostat

2. Control board and wiring

3. Blower housing assembly

4. Blower motor

5. Inducer motor and blower

6. Gas valve

7. Heat exchanger

8. Burner assembly

9. Lower cabinet

10. Upper cabinet

Diagram shows a mid-efficiency furnace.

How to identify your furnace type

Blower housing assembly

The blower housing assembly contains the blower impeller and motor. It is located in the lower cabinet, where it connects to the furnace filter and return system for air intake.

When the blower motor is running, the blower housing assembly directs air up through the heat exchanger and into the duct system.

Blower motor

The blower motor pulls air into the furnace from the return air system, passes it through the heat exchanger (and air conditioning coil, if you have one) then blows it out through your duct system.

The type of blower motor depends on the furnace. Single-stage furnaces have single-speed blower motors. Two-stage and variable-capacity furnaces have dual-speed or variable-speed blower motors.

The blower motor is located in the centre of the blower housing assembly in the lower cabinet.

Burner assembly

The burner assembly is where natural gas is mixed with combustion air and ignited to produce heat. The inducer motor draws heated air from the burners through the heat exchanger and out the exhaust flue.

In low-efficiency furnaces and some mid-efficiency furnaces, the burner assembly is open and the lit burners are visible inside of the upper cabinet.

In high-efficiency furnaces the burner assembly is closed inside a sealed burner box, which usually has a small viewport to view the lit burners.

Call for heat

A ‘call for heat’ is when the thermostat determines heating is required and signals the furnace to start up.

Some thermostats have a built-in delay before they call for heat. This is a feature to prevent short cycling the furnace — not a malfunction. See below for examples of common thermostats calling for heat.

Analog thermostats with no display call for heat when the temperature set by the slider (at the bottom) is higher than the indoor temperature measured on the dial at the top. There is often an audible 'click' as the thermostat switches the call for heat on or off.

When an Ecobee thermostat is calling for heat, a small orange flame is shown on the display above the temperature setting.

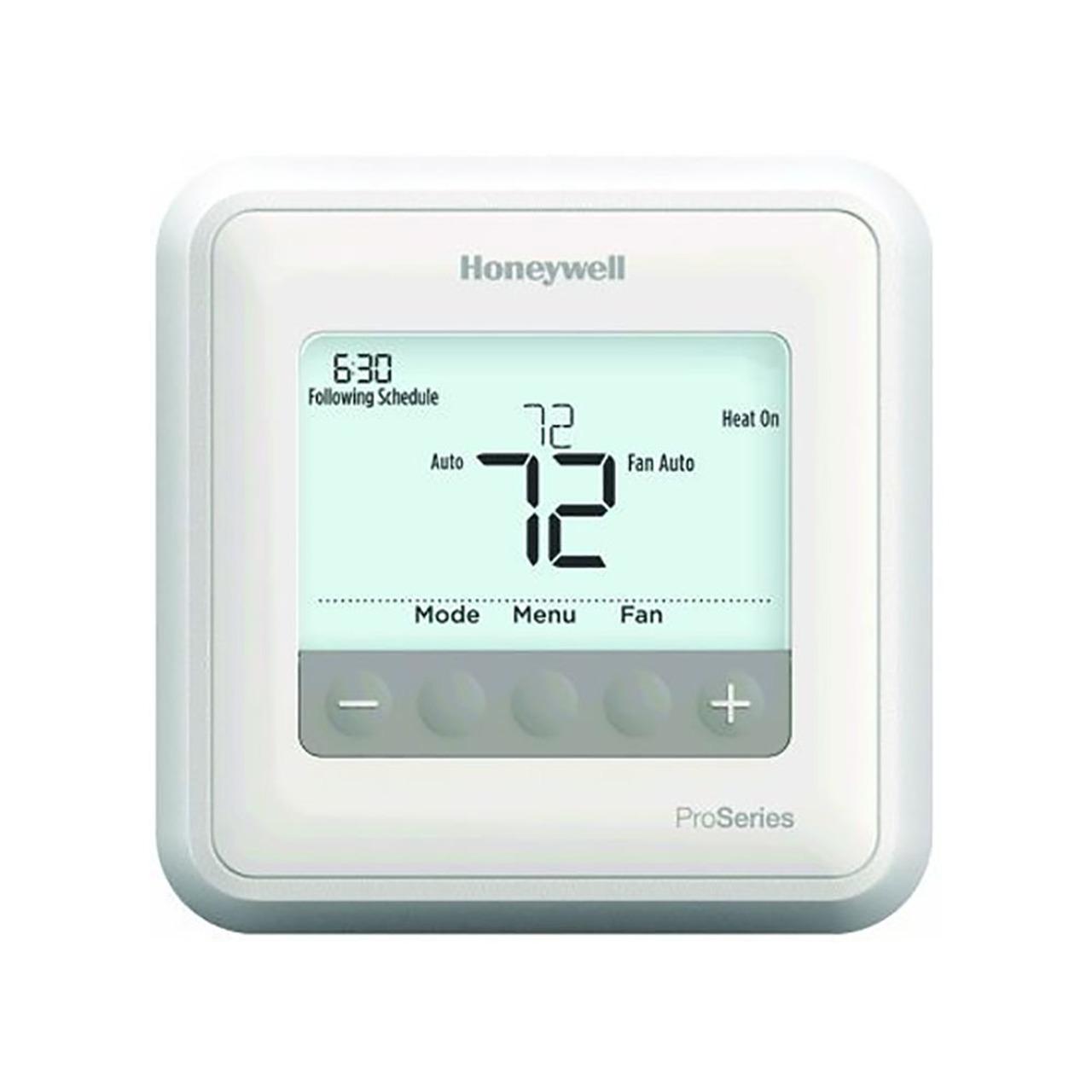

When a Honeywell T4 or T6 thermostat is calling for heat, 'Heat On' is shown on the display. If the 'Heat On' text is flashing, the call for heat was delayed and will start within 5 minutes.

When a Nest thermostat is calling for heat, the display turns orange and 'heating' is shown above the temperature setting.

Control board and wiring

The control board handles all aspects of furnace operation. It starts the furnace when the thermostat is calling for heat, and stops the furnace when the set temperature is reached.

The control board engages the inducer motor, gas valve, igniter, and blower motor in precise sequence for safe startup and operation. The newer the furnace, the more advanced the control system.

The control board is located in the lower cabinet and is connected by wires to all of the electrical components and sensors in the furnace.

Error codes are typically displayed on the control board or nearby.

Filter

The furnace filter cleans air before it enters the furnace, stopping dust, dirt, pet hair, and other particles from circulating through your home or damaging furnace components.

Furnace filters should be replaced every 90 days, before they become clogged and ineffective. Certain filter types and air quality conditions may require earlier replacement.

The furnace filter assembly is typically located directly between the furnace and return air duct system, where it connects directly to the blower housing assembly.

Flame sensor

The flame sensor is a safety feature that tells the furnace control system if natural gas is being burned. If the gas valve is open but the igniter fails or combustion stops, the flame sensor will alert the furnace to shut off the gas supply.

Mid- and high-efficiency furnaces have an igniter and flame sensor. Low-efficiency furnaces have a pilot light and thermocouple.

Gas valve

The gas valve controls the flow of gas to the burners. It activates when there is a call for heat and the furnace startup sequence has safely completed.

Single-stage furnaces have gas valves that are either “on” or “off.” Two-stage furnaces have two-stage gas valves with “high” and “low” output. Variable-capacity furnaces have modulating gas valves that can vary gas flow based on heating demands.

Low-efficiency furnaces have two gas valves: the pilot tube valve to provide gas to the pilot light, and the main valve to provide gas to the burners.

Heat exchanger

The heat exchanger transfers heat from combusted gas into the air pushed through your heating ducts.

The inducer blower draws combusted gas from the burners, through the heat exchanger, and out through the exhaust flue. Meanwhile, the blower motor pushes air across the heat exchanger and into the duct system.

The heat exchanger separates the furnace combustion system from the air that goes into your home, keeping it free of exhaust gases and combustion residue.

The heat exchanger compartment is at the rear of the upper cabinet, but is not visible even when the front panel is open.

Humidifier

A furnace-mounted humidifier maintains the set humidity level by moistening air as it passes through the duct system.

Bypass-style humidifiers (the most common type in Calgary) operate by “bypassing” the furnace with a short duct between the return air system and hot air trunk. When the furnace operates, air is pulled through the bypass duct and over the moistened humidifier drum or pad.

The humidifier requires a line for fresh water input, a drain for condensation disposal, and electricity leads to operate.

Igniter

The igniter is a hot-surface resistor or spark plug located in the burner assembly of mid- and high-efficiency furnaces. When the gas valve is opened, the igniter is engaged to light the burners.

Low-efficiency furnaces have a pilot light instead of an igniter.

Inducer motor and blower

The inducer is a small blower that circulates combustion air through the heat exchanger and pushes it out of the exhaust flue.

The inducer motor engages at the start of the ignition cycle to purge air and gas from previous cycles and intake the correct volume of air for high-efficiency combustion.

Limit switch

Limit switches are a critical safety feature of mid- and high-efficiency furnaces. They prevent the furnace from turning on or continuing to run if the internal furnace temperature exceeds a safe threshold. The primary limit switch is typically located in the upper furnace cabinet, below the burners, behind the gas valve and gas manifold.

Limit switches operate by temperature. When the switch is below the safe temperature, it remains closed and allows electrical current to flow. When the switch is above the safe temperature, it opens and prevents the flow of electrical current.

The furnace control board is always checking for electrical current from the limit switch(es) during furnace startup and normal operation. If it does not detect current from the limit switch, it closes the gas valve, sets the blower motor to run constantly, and displays a limit switch error code. The furnace will remain in this state until the limit switch cools down, resets itself, and closes.

Lower cabinet

The lower cabinet contains the blower housing assembly and (typically) the control board.

The lower cabinet maintains a cooler temperature because it is below the upper cabinet and separated from the burners and heat exchanger, which helps protect the control board and blower motor electronics.

Pilot light

The pilot light is a small flame that is always kept lit inside the burner assembly of low-efficiency furnaces. When the gas valve is opened, the pilot light ignites the gas to start the burners.

If the pilot light is not lit, a thermocouple disables the gas valve.

Mid- and high-efficiency furnaces have an electric igniter instead of a pilot light.

Roll out switch

Roll out switches are a critical safety feature of mid- and high-efficiency furnaces. Roll out switches ‘pop’ open when the temperature near the furnace burner box exceeds a safe threshold, which prevents the furnace from turning on or running. The roll out switch(es) are located on the sides of the burner box.

Roll out switches are normally closed and allow current to flow. The furnace control board is always checking for electrical current from the roll out switch(es) during furnace startup and normal operation. If it does not detect current from a roll out switch, it closes the gas valve and enters a hard lock out until the roll out switches are reset.

Unlike limit switches, roll out switches must be manually reset after they pop open.

Thermocouple

A thermocouple is a simple, temperature-controlled electrical switch. Low-efficiency furnaces use a thermocouple to disable the gas valve if the pilot light is not lit.

Mid- and high-efficiency furnaces have a flame sensor instead of a thermocouple.

Thermostat

The thermostat measures the indoor air temperature and calls for heat from the furnace as needed to maintain the set temperature. It is connected directly to the furnace control board with low voltage wires.

Some newer furnaces are paired with thermostats that provide smart features, maintenance reminders, and error code reporting.

Smart thermostats such as Nest and Ecobee can connect to most furnaces to provide extra features and programmability.

Home with multiple heating zones typically have multiple thermostats, each one paired with a specific furnace.

Upper cabinet

The upper cabinet contains the inducer motor and blower, gas valve, burner assembly, and heat exchanger.